-

KOSPI 2577.27 -2.21 -0.09%

-

KOSDAQ 722.52 -7.07 -0.97%

-

KOSPI200 341.49 +0.02 +0.01%

-

USD/KRW 1396 -2.00 0.14%

LG developing technology to produce cathode without precursors

Batteries

LG developing technology to produce cathode without precursors

Precursors emit greenhouse gases and account for a large portion of electricity use during the cathode manufacturing process

By

Aug 01, 2023 (Gmt+09:00)

1

Min read

News+

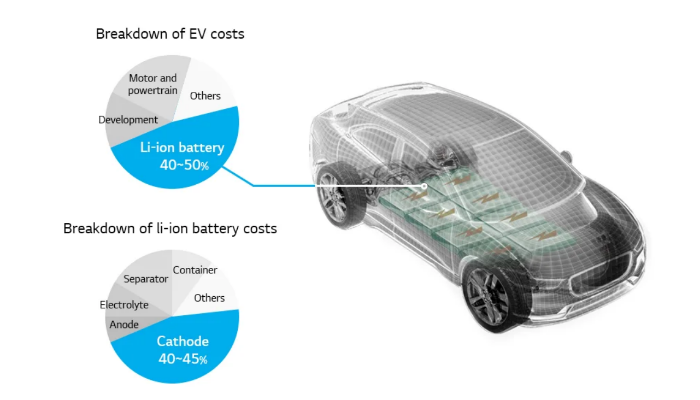

LG Chem Ltd. has embarked on a new technology development to produce cathodes without precursors in a bid to slash battery manufacturing costs and meet carbon neutrality commitments, an LG Chem official said on Tuesday.

A precursor is an ingredient of a cathode, one of four key materials of an electric vehicle battery. It accounts for 60-70% of the cost of manufacturing cathodes.

A precursor is a chemical compound of metals such as nickel, cobalt and manganese and turns into a cathode with the addition of lithium.

Precursors contain nitrogen dioxide and sulfur dioxide, so they emit greenhouse gases during the manufacturing process, while consuming more electricity than other battery materials.

Cathodes without precursors will be regarded as eco-friendly because they will not generate wastewater or toxic gas.

“We’re developing the technology at our client’s request to produce low-carbon products,” the LG Chem official told The Korea Economic Daily.

“It hasn’t been decided yet when we can commercialize it.”

LG uses the coprecipitation technique to make precursors, in which more than one compound from a solution undergoes the process together. A precursor is produced after the mineral solution containing the compounds is cleaned and dried.

By comparison, the new technology under development will dissolve both metals and lithium simultaneously and take cathodes in a liquid form in the wet grinding process.

Once the technology is commercialized, South Korean battery makers will not need to rely on the China-dominated precursor value chain. China commands 90% of the global precursor market.

Cathode production eliminating the precursor manufacturing process will significantly improve production yields and cut battery manufacturing costs, according to SNE Research.

The research house said it will be also easier to recover metal from used batteries made from cathodes without precursors.

LG Chem will diversify its cathode product portfolio to meet customer demand.

It is now building precursor plants in partnership with China’s Huayou Cobalt and Korea Zinc Inc.

Write to Hyung-Kyu Kim at khk@hankyung.com

Yeonhee Kim edited this article.

More To Read

-

Jun 26, 2023 (Gmt+09:00)

-

Jun 02, 2023 (Gmt+09:00)

-

May 31, 2023 (Gmt+09:00)

-

Apr 14, 2023 (Gmt+09:00)

-

Mar 23, 2023 (Gmt+09:00)

-

Nov 22, 2022 (Gmt+09:00)

-

Jun 02, 2022 (Gmt+09:00)