-

KOSPI 2577.27 -2.21 -0.09%

-

KOSDAQ 722.52 -7.07 -0.97%

-

KOSPI200 341.49 +0.02 +0.01%

-

USD/KRW 1396 -2.00 0.14%

POSCO International wins $761 mn EV parts supply deal from US carmaker

Electric vehicles

POSCO International wins $761 mn EV parts supply deal from US carmaker

The US client is said to be GM, already in a business partnership with POSCO

By

Nov 08, 2023 (Gmt+09:00)

3

Min read

News+

POSCO International Corp., the general trading and energy exploration unit of South Korea’s steel giant POSCO Holdings Inc., has won a 1 trillion won ($761 million) deal to supply electric vehicle components to a US automaker.

POSCO International recently signed the deal to supply the unidentified US carmaker with EV traction gears from next year through 2032.

Industry officials said the US client is General Motors Co., although POSCO declined to confirm it.

“We cannot identify the client’s name due to a confidentiality agreement,” said a POSCO International official.

The company plans to build a traction gear factory in the US if requested to do so by the client.

Separately, POSCO International recently clinched a 150 billion won deal to supply drive motor shafts to another US automaker. The EV parts will be supplied from 2024 to 2031.

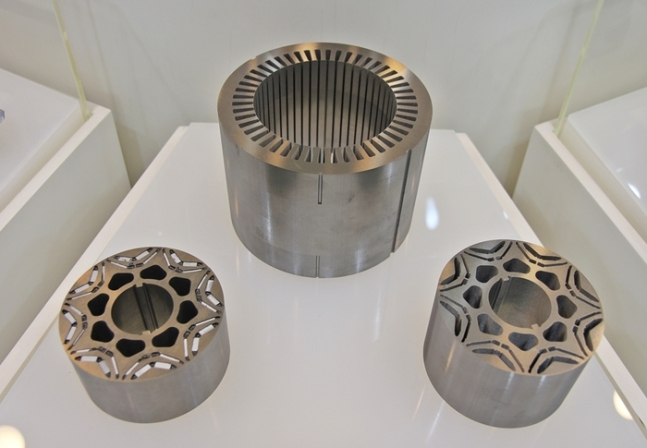

An electric vehicle needs a drive motor to run, like a powertrain in a combustion engine car, and motor cores to convert electric power into kinetic energy for motion.

POSCO’S KOREAN PARTNERS

EV traction gears will be manufactured by a small Korean company and POSCO International will supply them to its US client.

POSCO has been accelerating its push to expand its presence in the electric vehicle supply chain, one of seven growth drivers defined by the steel conglomerate to diversify its business portfolio beyond steel.

The seven growth engines targeted by the group are the steel, hydrogen, rechargeable battery materials, lithium and nickel, energy, construction and food industries.

POSCO Group Chairman Choi Jeong-woo said in April that POSCO International plans to reinforce its energy exploration and production value chain to turn into a green company by 2030.

POSCO International operates its EV parts business through its subsidiary, POSCO Mobility Solutions, Korea’s No. 1 motor core maker.

In September, POSCO International signed a contract to supply 3.5 million traction motor cores to Hyundai Motor Group.

A traction motor core, dubbed the second heart of an EV as it generates power for an electric motor, makes up about 40% the expense of producing a motor. The motor accounts for about 15% of EV manufacturing costs, the second-largest after batteries, which make up some 30%.

According to research firm Verified Market Research, the global EV traction gear market is forecast to grow to $2.3 billion by 2027 from $152 million in 2019.

DIVERSIFYING BUSINESS PORTFOLIO

POSCO International has been diversifying its business portfolio recently.

It is seeking to build a factory in the US to produce permanent magnets, an essential part of an EV drive motor core, jointly with Korean rare earth permanent magnet hidden champion Star Group Industrial Co.

POSCO International is also considering launching a joint venture with Kumho Petrochemical Co. to produce carbon nanotubes (CNTs), a next-generation battery material.

CNTs have very high heat conductivity, comparable to that of diamond crystal and copper, and can be more than 100 times stronger than steel.

The material has been used in various sectors such as semiconductor processing trays, automotive conductive coatings and car exterior materials.

More recently, it has been used as a rechargeable battery material. CNTs increase the volume of cathodes in batteries, thus extending cell capacity and lifespan.

Write to Hyung-Kyu Kim at khk@hankyung.com

In-Soo Nam edited this article.

More To Read

-

Nov 01, 2023 (Gmt+09:00)

-

Chemical IndustryKumho Petrochem, POSCO look to carbon nanotube JV, share swap

Chemical IndustryKumho Petrochem, POSCO look to carbon nanotube JV, share swapOct 27, 2023 (Gmt+09:00)

-

Electric vehiclesPOSCO Int’l completes Mexico EV motor core plant for N.American market

Electric vehiclesPOSCO Int’l completes Mexico EV motor core plant for N.American marketOct 18, 2023 (Gmt+09:00)

-

Sep 15, 2023 (Gmt+09:00)

-

Corporate strategyPOSCO International to transform into green company by 2030

Corporate strategyPOSCO International to transform into green company by 2030Apr 13, 2023 (Gmt+09:00)