Get It Made in Korea

Dong-A ENG Co.Molding & Casting

The 30-year-old Korean mold manufacturer boasts expertise in manufacturing molds with advanced materials.

Key facts

| Industry | Mass-production mold design and manufacturing/machinery manufacturing |

| Mainstay products/services | Automotive interior molds, GMT/low-pressure injection molds, SMC molds, other special lightweight, advanced material molds |

| Technology forte | R&D center for advanced molds, such as lightweight, high functional molds, RTM PU molds, press molds, steaming molds, hot/cold forming molds, forming and trimming molds. Automatic surface treatment facility |

| Main customers | Automotive, electronics, aerospace firms from Europe, Korea, Japan |

| Headquarters | Siheung, Gyeonggi-do, South Korea |

| Overseas expansion | Factories in Korea, the Czech Republic, Thailand |

| Founding year | 1992 |

Why it stands out

Korean mold maker Dong-A ENG advances with green mobility

Dong-A ENG Co., a South Korean industrial mold manufacturer founded in 1992, is a vital player in green car development thanks to its mastery in designing and manufacturing molds for automotive parts made of advanced materials.

“It is a must to develop lightweight materials, the key to improvement in fuel efficiency, which is a top consideration for consumers when purchasing cars.”

To meet the growing demand for lightweight materials in the auto industry, Dong-A ENG has put massive time and effort into researching advanced materials, as well as the latest mold techniques and manufacturing processes to develop high-performance molds.

This effort has paid off, making the company a trusty partner of automotive component makers in Korea.

MOLDS MADE OF ADVANCED MATERIALS

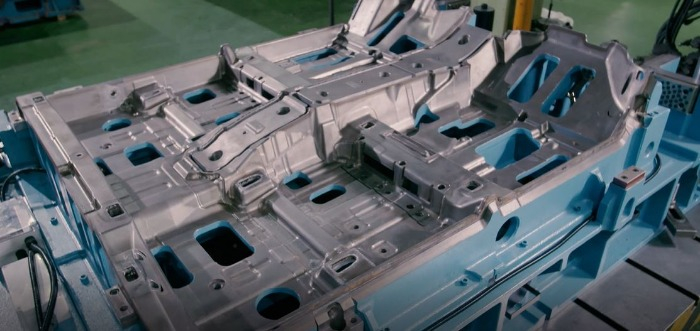

While molds, in general, are made of metal or steel, Dong-A ENG uses advanced materials such as carbon fiber, glass wool mat, polyurethane (PU) and glass fiber to make special molds for lightweight auto parts.It designs and manufactures hot/cold forming molds, steam/vacuum forming molds, foaming molds and inset molds for automotive interior parts and noise, vibration and harness (NVH) parts.

It also produces glass fiber mat reinforced thermoplastics (GMT) and low-pressure injection molds, sheet molding compound (SMC) molds and molds for special parts used in electronics, aircraft parts and military weapon parts.

Dong-A ENG, however, is a traditional mold company, designing and producing not only special molds for car parts made of advanced materials but also general molds for injection molding and press molding.

ONE-STOP MOLD MANUFACTURING SERVICES

As a mold manufacturing company with extensive know-how, Dong-A ENG offers its customers one-stop mold manufacturing services from design to manufacturing, testing and prototype production. It can make immediate changes to a mold design upon a customer’s request, which can save customers both time and money. The prices of its molds are also about 30% to 40% cheaper than those of imported molds, according to the company.

With its own machines and equipment, ranging from hydraulic presses to oil and steam boilers as well as an oven and vacuum pump, Dong-A ENG can produce up to 100 prototype products with one newly made mold, a process that will enable a customer to pretest the performance of its new mold before deciding to build mass-production facilities.

This is especially a plus for a fledgling business without manufacturing facilities, allowing it to reduce the risks associated with building a mass-production line.

BIG SPENDER ON R&D WITH CERTIFIED TECHNOLOGIES

The competitiveness and quality of molds made of advanced materials heavily depend on the manufacturing know-how of each supplier because companies use different methods, as well as machines and equipment to manufacture molds.Dong-A ENG boasts technological prowess in mold designing and manufacturing thanks to its in-depth R&D capabilities.

It has its own R&D center and is certified for various mold manufacturing methods and materials. It also owns several patents related to mold manufacturing and materials.

It already conducted 10 state-sponsored projects in Korea and is now working on two other state-commissioned studies.

It is currently building an automated mold design system with advanced technologies.

READY TO SECURE MORE OVERSEAS ORDERS

The company generates about 70% of its sales from exports, mainly from Europe. It operates mold design and manufacturing factory in the Czech Republic to meet the specific demands of its European customers.

Exports to Europe account for 30% of its total sales, Japan 20% and Southeast Asia and Russia each 10%.

It entered the European market with its mold exports to Germany in 2009 and expanded its customer base in the region after taking over a mold factory in the Czech Republic from a German company in 2012, giving Dong-A ENG access to advanced mold manufacturing technologies.

It also runs a factory with maintenance facilities in Thailand and is seeking to build more overseas operations to further reach foreign customers.

Write to Sookyung Seo at skseo@hankyung.com

Jennifer Nicholson-Breen edited this article.