-

KOSPI 2577.27 -2.21 -0.09%

-

KOSDAQ 722.52 -7.07 -0.97%

-

KOSPI200 341.49 +0.02 +0.01%

-

USD/KRW 1396 -2.00 0.14%

Hyundai ushers in future of car manufacturing in Singapore

Hyundai Motor Group Innovation Center Singapore houses a conveyor belt-free car factory, an R&D center and a test circuit

By

Nov 21, 2023 (Gmt+09:00)

SINGAPORE – Hyundai Motor Group on Tuesday officially inaugurated its first mobility innovation center in Singapore powered by a slew of smart technologies, which will serve as the South Korean auto giant’s smart urban mobility hub to innovate its mobility research & development, manufacturing and business practices.

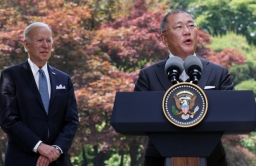

“HMGICS is an open and connected urban innovation hub that encourages and embraces creativity and collaboration. It seeks to completely redefine the very concept of manufacturing,” Hyundai Motor Group Executive Chairman Chung Euisun said at the opening ceremony of the Hyundai Motor Group Innovation Center Singapore (HMGICS).

“We will build innovative mobility solutions with HMGICS that can bring positive impacts to human evolution.”

Located in Jurong Innovation District, the seven-story HMGICS facility with a floor area of about 90,000 square meters houses a car manufacturing factory, a research and development center, a rooftop test circuit and a car delivery space for customers.

The manufacturing factory with an annual production capacity of 30,000 electric vehicles is built and operated with cutting-edge smart technologies and customer-centered services.

Hyundai Motor plans to produce purpose-built vehicles (PBV) and advanced air mobility (AAM) from its Singapore factory later, which currently manufactures electric vehicles – mostly the IONIQ 5 and self-driving robotaxis.

Along with the Ulsan factory, HMGICS will play a key role in leading Hyundai Motor’s automotive electrification for the next 5 decades to become a 100-year-old car company, the company said.

CONVEYOR BELT-FREE SMART FACTORY

The car factory inside HMGICS is free of the traditional conveyor manufacturing system as it adopts a cell-based manufacturing system, which requires only one person and one robot in each cell to assemble a car.

Instead of conveyor belts, self-driving robots fitted with LiDAR and other sensors move parts among 27 cells in the HMGICS factory floor. Automated guided vehicles also move partly assembled car bodies between cells along the navigation code-embedded lines on the floor.

Boston Dynamics Inc.’s mobile robot Spot will inspect car assembly conditions. Spot will take a photo of each assembly part and analyze it with an artificial intelligence algorithm to inspect the quality.

The US mobile robot developer was acquired by the Korean auto giant in 2021.

The cellular manufacturing system is great for the production of customized goods in small volume.

“With the help of robotics, AI, and the Internet of Things (IoT), we’ve built a human-centric manufacturing innovation system that can respond to changes in mobility, processes and products with agility and flexibility,” said Alpesh Patel, vice president and head of Technology Innovation Group at HMGICS.

“These innovations are setting new benchmarks for efficiency and customization.”

TWIN FACTORY AND IMMERSIVE CUSTOMER EXPERIENCE

The new factory is also supported with a three-dimensional virtual factory built by digital twin technology, which enables creation of a twin virtual model accurately reflecting a physical object.

For seamless and flawless connection and operation between the physical and virtual factories, the whole factory runs on a 5G network.

The HMGICS also offers an advanced customer-centered platform that allows customers to order cars via smartphones from home, view their cars’ assembly process through a virtual reality tour and test-drive their cars on the rooftop of the center building before their car delivery.

The building was constructed with a 618-meter Skytrack on the rooftop.

Hyundai Motor Group spent 700 billion won ($543 million) for three years to build the innovation center in Singapore.

The opening of HMGICS comes about a year later than its originally planned opening date of end-2022 due to the COVID-19 pandemic.

Hyundai Motor chose Singapore as its mobility innovation hub because the city state is open to the outside world and offers big support to new ideas, the company said. The country also has a great talent pool.

The Korean auto company will test its future mobility solutions in Singapore and check the market response before applying the new technologies in other parts of the world, it added.

Write to Il-Gue Kim at black0419@hankyung.com

Sookyung Seo edited this article.

-

Electric vehiclesHyundai breaks ground on $1.5 bn EV plant in S.Korea

Electric vehiclesHyundai breaks ground on $1.5 bn EV plant in S.KoreaNov 13, 2023 (Gmt+09:00)

-

May 24, 2022 (Gmt+09:00)

-

Electric vehiclesGeorgia state to provide $1.6 bn in incentives to Hyundai

Electric vehiclesGeorgia state to provide $1.6 bn in incentives to HyundaiMay 23, 2022 (Gmt+09:00)

-

Electric vehiclesHyundai to invest $10.5 bn in US EV, future mobility sectors

Electric vehiclesHyundai to invest $10.5 bn in US EV, future mobility sectorsMay 22, 2022 (Gmt+09:00)

-

Electric vehiclesRobots, AI replace human workers at Kia’s EV6 manufacturing factory

Electric vehiclesRobots, AI replace human workers at Kia’s EV6 manufacturing factoryNov 22, 2021 (Gmt+09:00)

-

Future mobilityHyundai eyes smart mobility with Boston Dynamics acquisition

Future mobilityHyundai eyes smart mobility with Boston Dynamics acquisitionJun 21, 2021 (Gmt+09:00)

-

Oct 13, 2020 (Gmt+09:00)